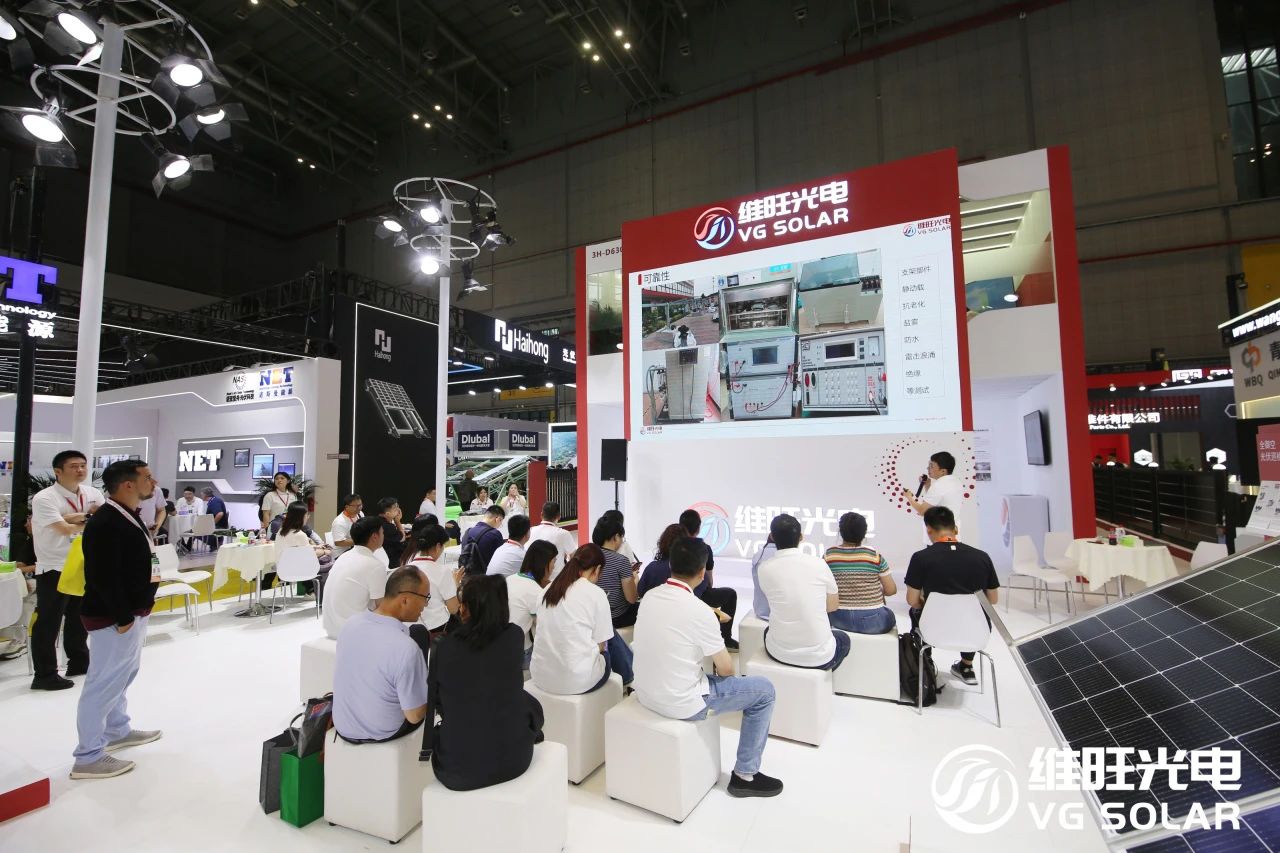

From June 11th to 13th, the 18th SNEC 2025 International Solar Photovoltaic and Smart Energy Conference and Exhibition (Shanghai) was grandly held at the National Exhibition and Convention Center (Shanghai). As a globally leading expert in photovoltaic bracket system solutions, VG Solar showcased a variety of upgraded bracket solutions, with “intelligence + efficiency” at its core, comprehensively demonstrating its leading strength in product innovation, system integration and scene adaptation.

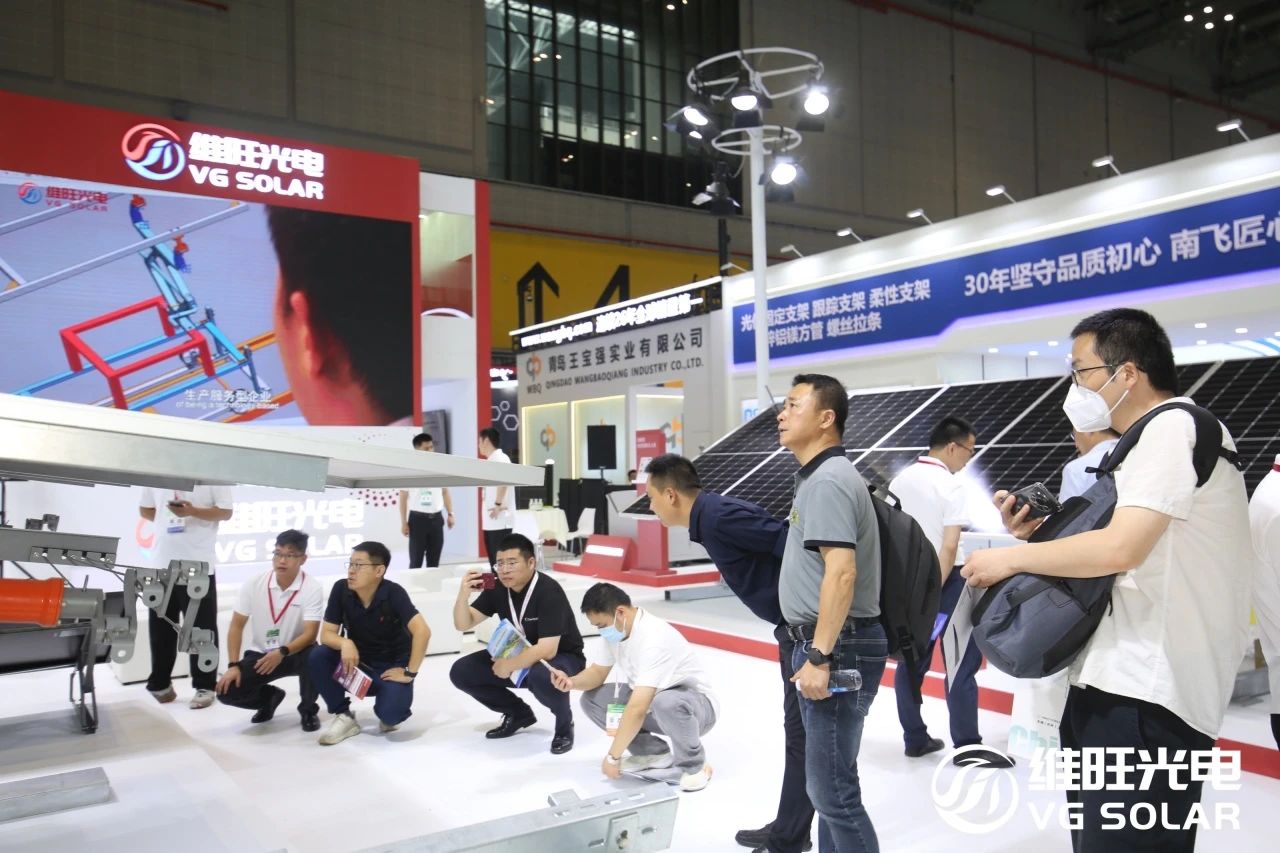

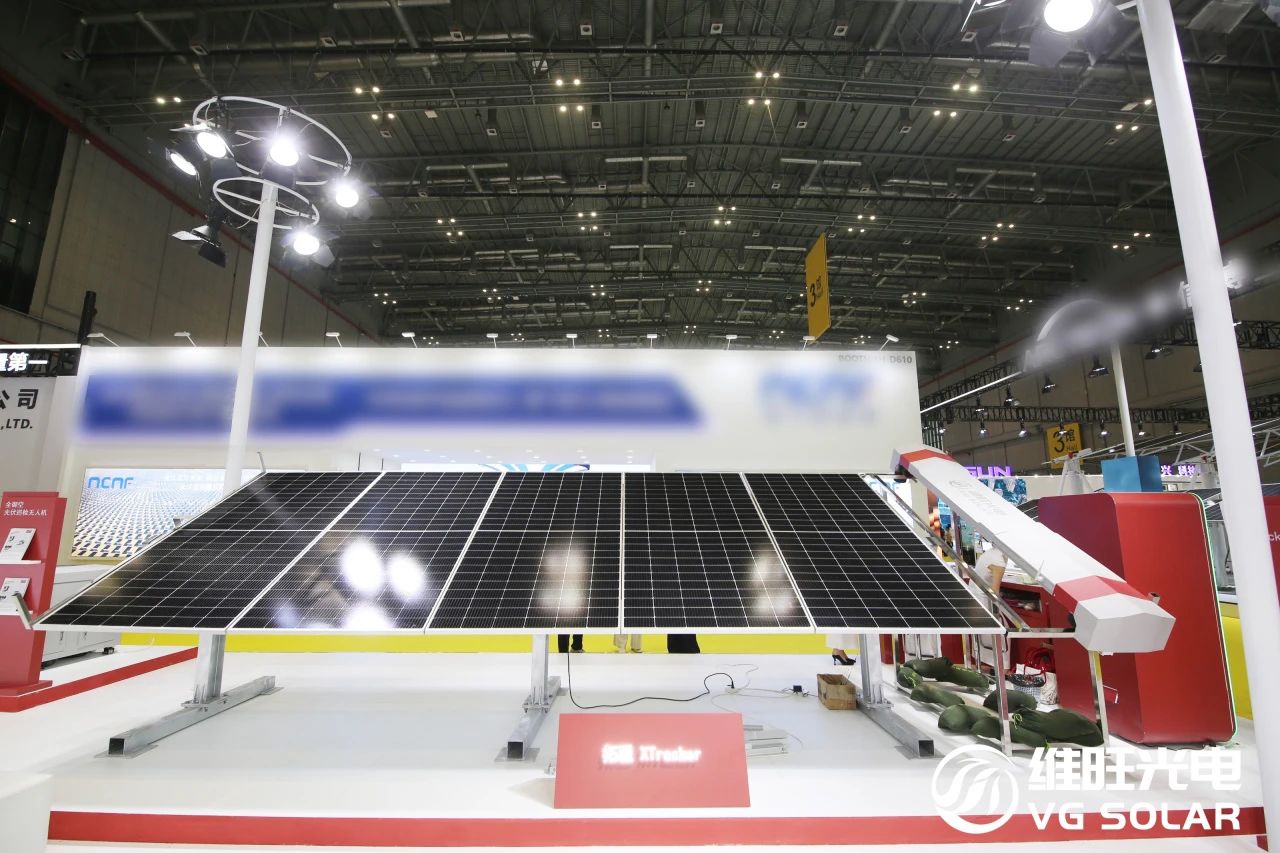

Among them, the newly upgraded multi-scenario comprehensive solution, with its high adaptability to diverse application scenarios, has become the focus of attention at the exhibition site. This solution deeply integrates the “XTracker” series tracking system, “SolarPath H200″ cleaning robot and “SolarSight” inspection robot independently developed by VG Solar. Through intelligent collaboration and data intercommunication, it builds an intelligent management system covering the entire life cycle of photovoltaic power stations, achieving full-process closed-loop control from power generation efficiency optimization to operation and maintenance management upgrade. Drive a significant improvement in the overall system efficiency.

The “XTracker” series of tracking systems have undergone technological iterations and upgraded intelligent control

As the core of a multi-scenario comprehensive solution, the “XTracker” series of tracking systems have achieved a new round of technological upgrades. The rotary reducer equipped in the new product adopts an integrated design of brushless motor and built-in drive board, achieving multiple breakthroughs in space utilization, system stability and operation and maintenance cost control.

Compared with the previous generation of products, the “XTracker” series has significantly improved in terms of lifespan, maintenance frequency and control accuracy, and is particularly suitable for large-scale ground-mounted power station projects in complex terrains and diverse climate environments. Its high-precision Angle adjustment capability can maximize the light-receiving area of the components and further enhance the overall power generation revenue of the power station.

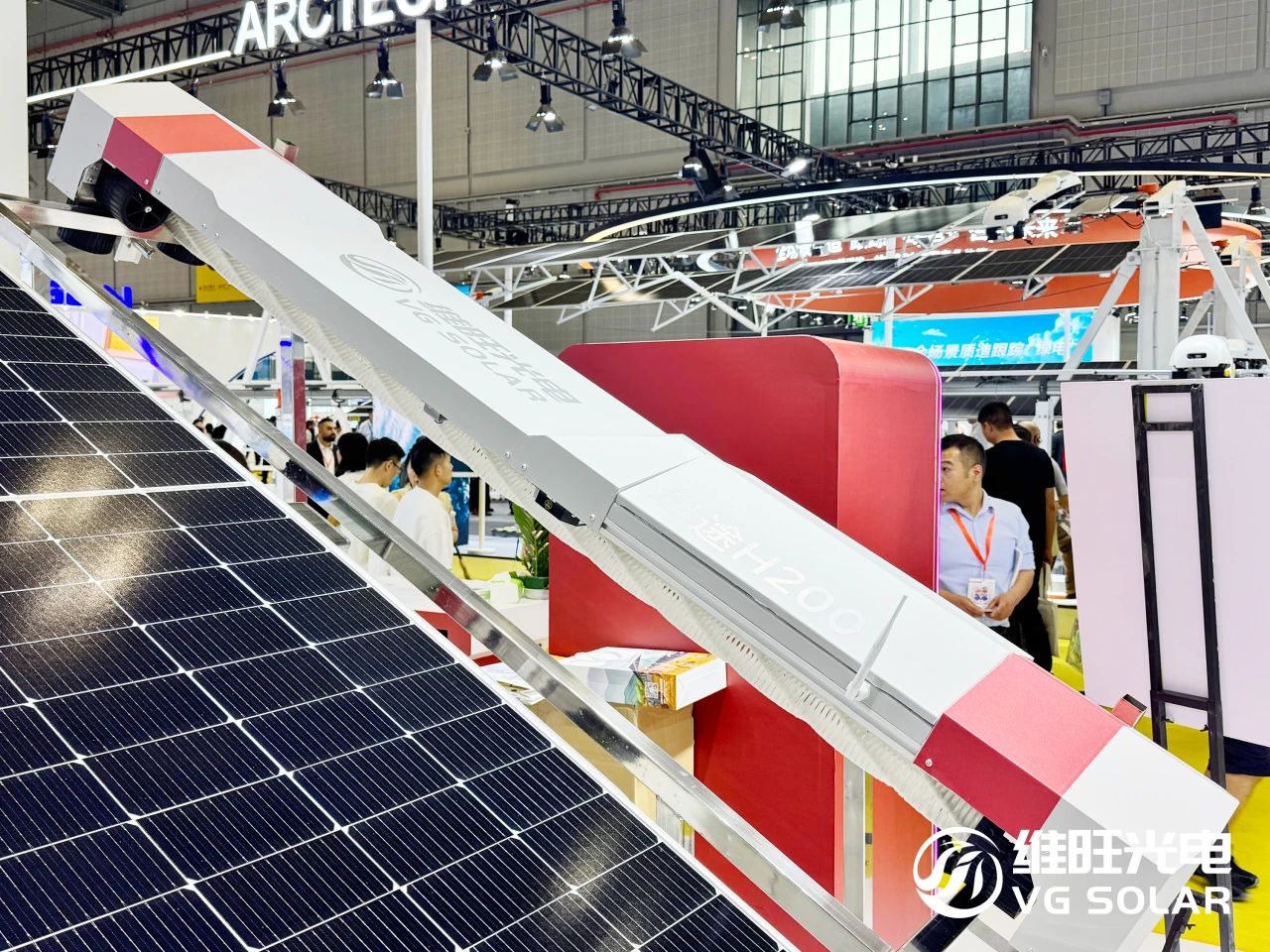

The “SolarPath H200″ cleaning robot has been comprehensively optimized for more efficient cleaning

The “Tantu H200″ cleaning robot, which is paired with the “SolarPath H200″ series tracking system, has also demonstrated brand-new performance advantages after the upgrade. Compared with the previous generation of products, this robot has reduced its weight by 20%, effectively lowering wind resistance and reducing the pressure burden on the component surface.

Facing the challenge of frequent extreme weather, the “SolarPath H200″ has added a strong wind shutdown protection mechanism, which can safely lock in strong winds of up to level 15 to ensure the stable operation of the equipment. In terms of cleaning performance, the robot can easily overcome obstacles of 40mm, with a maximum climbing Angle of 25° and a cleaning efficiency as high as 99.5%. It supports both wireless charging and self-backlit photovoltaic panel dual-mode power supply, ensuring continuous operation in various environments and truly achieving all-weather unattended cleaning.

The “SolarSight“ inspection robot has intelligent perception, making operation and maintenance more accurate

The “SolarSight” inspection robot, equipped with high-precision infrared thermal imaging and AI image recognition technology, serves as the “sentinel in the air” of VG Solar‘ intelligent operation and maintenance system. It can conduct all-weather autonomous inspections of components, brackets and electrical equipment, monitor the operating status in real time, and accurately locate the fault points.

By integrating the data analysis capabilities of the cloud platform, the system can automatically generate operation and maintenance reports and issue early warnings of potential risks, significantly enhancing response speed and the intelligence level of operation and maintenance. This not only reduces the cost and safety risks of manual inspection, but also provides a strong guarantee for the long-term stable operation of photovoltaic power stations.

The coordinated operation of the three has built an integrated operation and maintenance system of “intelligent tracking + automatic cleaning + efficient inspection”, truly achieving efficiency improvement throughout the entire chain from the power generation end to the operation and maintenance end. The multi-scenario comprehensive solution developed by Vivon Optoelectronics not only showcases the company’s profound strength in technological innovation and system integration, but also precisely aligns with the future development direction of the photovoltaic industry towards “intelligence, intensification, and ecologicalization”. It is an important practice for promoting the transformation of power stations towards high-quality and sustainable operation.

Under the guidance of the “dual carbon” strategic goals, VG Solar has always adhered to customer needs as the core, deeply integrated cutting-edge technologies with engineering practice experience, continuously expanded the application boundaries of photovoltaic systems, and helped global customers achieve more efficient and valuable energy management and green sustainable development goals. The future is here. VG Solar will continue to “support” the boundless possibilities of green energy with innovative solutions, allowing every ray of sunlight to release greater value.

Post time: Jun-19-2025